The Importance of Subfloor Prep

Regardless which type of resilient flooring is being installed, every floor will require some kind of subfloor prep. Every installation is unique and will have its own subfloor prep requirements. Careful and correct preparation of the subfloor is a major part of a satisfactory resilient floor covering installation. Roughness or unevenness of the subfloor will telegraph through the new floor covering, resulting in an unsightly surface and excessive wear on high spots. Proper subfloor preparation and suitable underlayment installation are essential for a trouble-free job.

Before proceeding with any installation, there are a few questions to factor in before proceeding;

- What type of flooring is to be installed?

- Commercial floors generally have a smooth face and will show any subfloor defects

- For most Resilient flooring, subfloor flatness is 3/16 of an inch in 10 feet

- New Construction or Remodel?

- If it is remodel, what flooring was previously installed and how was it removed?

- What condition is the subfloor in?

- Five words to remember in subfloor prep;

- Clean

- Smooth

- Structurally Sound

- Level

- Dry

- Five words to remember in subfloor prep;

- Has the subfloor been tested for Moisture and pH?

- All concrete subfloors on any level should be tested for moisture and pH and documented

- Hardwood installations over wood subfloors should be checked for moisture and documented

- Have sealers or curing compounds been used?

- What is the subfloor and what is it over?

- Concrete, Gypsum, or Wood

- Crawl Space?

All of these and other conditions can vary from job to job. Each set of unique conditions has a very specific series of steps required to prepare the substrate prior to installing the prep materials and then, the finish flooring. The finished floor is only as good as the base or the subfloor is. The make-up of the subfloor and the condition and quality of the subfloor, directly affect the performance of the finished resilient flooring. If the system components are not as recommended or as required, the flooring can fail. If the condition of the subfloor is poor, not properly cleaned, not dry enough, and not flat enough, the flooring performance will suffer and require a call back and some type repair, maybe even reinstallation. Problems related to improper subfloor preparation continue to multiply each year, with millions of dollars in damage as a result. Sadly, most of these problems are preventable when correct installation methods are followed. Before starting any installation, it is critical to make sure that the subflooring is ready to have flooring installed over it. There are now countless specialized products to help installers ensure that subfloors are clean, flat and dry enough to install flooring over. In order to use them effectively, you need to take the time to learn about the latest products and installation methods. Not prepping a floor correctly is only going to lead to bigger issues that will come back to you. A customer that does not want to pay for prep is only setting themselves up for a disappointing flooring failure. Improper subfloor prep is my #2 issue with floating floors. People think floating floors can go over and cover anything, which leads to failure. Floating floors were not made to cover a bad subfloor. Lack of expansion zone is my #1 issue.

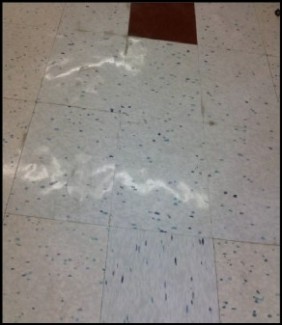

High spots in subfloor getting burned while burnishing

Wavy & uneven subfloor telegraphing.

Owner did not want to pay for prep, now he’s complaining

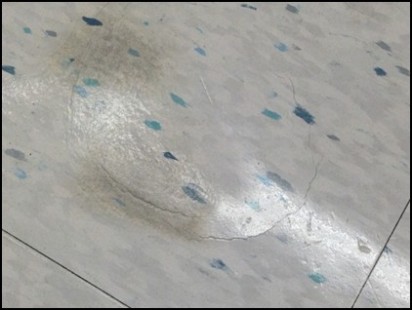

Poor concrete. Existing Tile was removed and did this to the subfloor.

GC wanted flooring contractor to only skim the floor, not take care of the subfloor issue.

Subfloor out 1/2″ in 12″. Owner complaining about burnish marks

Tile cracking over raised areas in subfloor

Special Thanks to JJ Haines for the info!